ONE-COMPONENT MOISTURE CURED PU

One-component or Single-component moisture curing polyurethane adhesive precision dosing and applying technology

1-Component polyurethane adhesives are moisture curing single component systems which typically consist of non-volatile urethane prepolymers and require moisture to trigger the curing reaction, linking with moisture from the air and the substrate

The bonds are extremely strong and temperature and water resistant. Cured adhesives range from hard and rigid to soft and flexible depending on formulation, that allows to make a wide field of application for difficult to bond materials like plastics, galvanized steel.

That provides using of single component PUR in:

- various sandwich panel bonding with OSB, MgO, PVC, fiberglass, fiber cement boards, etc, with different core materials as EPS, XPS, foamed PUR, PIR, mineral wool, wood wool;

- all types of wood, thermowood, hardwood;

- bonding textile materials

Perfect properties of the single component PUR allows to use it in manual and automatic modes. As adhesive is a moisture reactive, PUR adhesive applying machinery must be fully hermetic to prevent reaction inside. Gluestream machinery designed for using PUR adhesive in a wide range of viscosity and density. Our pumps provide a high accuracy of the glue dosing, despite the difference of the adhesive viscosity, allowing to work in a wide temperature range. The pumps are tested by a long term of working in hundreds our machinery and no one pump have been changed yet.

Automatic equipment and software has wide possibilities to control and monitor the production process with possibility of remote access for diagnostic and adjusting machinery via internet.

Main business field where our 1-component PUR applying machinery is used:

- building and construction for manufacturing various types of sandwich panels, SIPs;

- PVC sandwich panels manufacturing, for PVC and aluminum doors;

- wooden doors and windows manufacturing;

- construction wooden elements manufacturing, KVH, BSH timbers, CLT panels, OSB i-beams;

- multilayer wooden parquet;

- refrigerated panels manufacturing;

- clean room panels manufacturing;

- truck body panels manufacturing;

- steel wall and roof panels;

- steel doors panels;

- cleaning sponges manufacturing.

You can discover Gluestream machinery for one-component polyurethane glues precision applying and technology right here below:

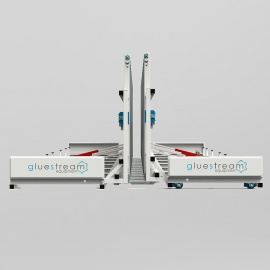

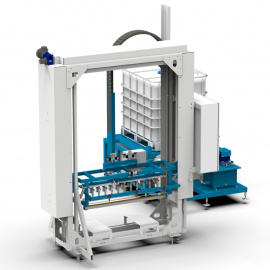

GLM-10 1-C PUR GLULAM

One-component polyurethane (1-C PUR) adhesive applying machine with automated START/STOP drive system

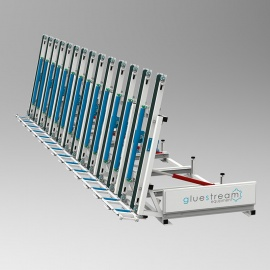

GLM-10 SWAN GLULAM

One-component polyurethane (1-C PUR) adhesive applying machine with automated belt conveyor

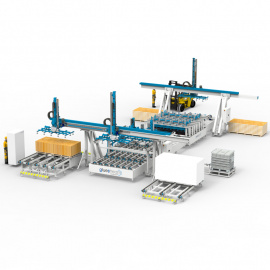

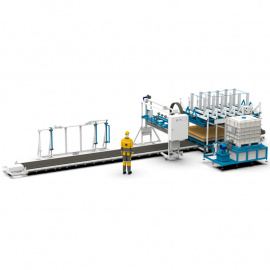

PVC HPL SANDWICH PANEL PRODUCTION LINE

Sandwich panel production line with automatic gluing, pressing and CNC edge cutting band saw

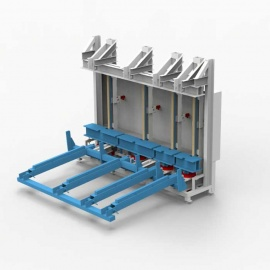

SPL-1 SANDWICH PANEL PRODUCTION LINE

Sandwich panel (SIP) production line with one driven carriages and one P-type pneumatic presses

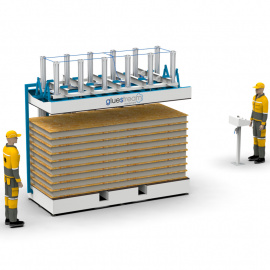

ASPL-10M AUTOMATIC SIP PRODUCTION LINE

Sandwich panel production line with motorized roller conveyor combined with several P-type presses.

Sandwich panel production line with motorized roller conveyor combined with several P-type presses.